3D Printing – Settings, Photos, Problems

With more than expected traffic on the 3D printer setup and instructions… a few comments that might help.

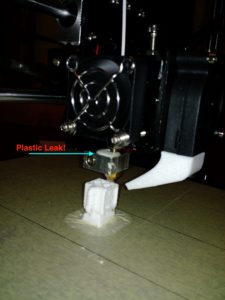

PROBLEM: Leak in printer nozzle

The printer nozzle initially leaked melted plastic through the threads and later broke when I tried to tighten it… (while it was hot). If you look at the last photo in the build instructions, there was a small puddle of white plastic on the top of the printer nozzle as it made the test part. This is not supposed to happen. The threads are large and didn’t seal correctly to hold in the melted plastic.

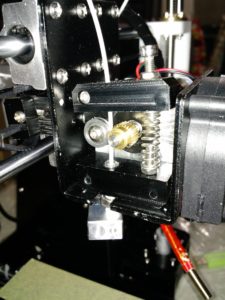

Eventually, the plastic flowed over the printer nozzle and onto the part. Not good… So, I removed the plastic and cleaned the extruder head with solvents – very messy. Re-assembled everything, tighter. Yea, it didn’t fix the problem. Actually, plastic started leaking from both ends of the extruder. When I tried to over tighten the nozzle and feed tube, the threads cracked in the housing (see photo below). I ended up replacing the entire heated nozzle assembly. Lesson: Do not try to over tighten anything on the printer.

SOLUTION: With the new extruder, I wrapped PTFE (Teflon) pipe tape on the threads. Problem solved. No more leaks. Also, PTFE melts at 327°C.

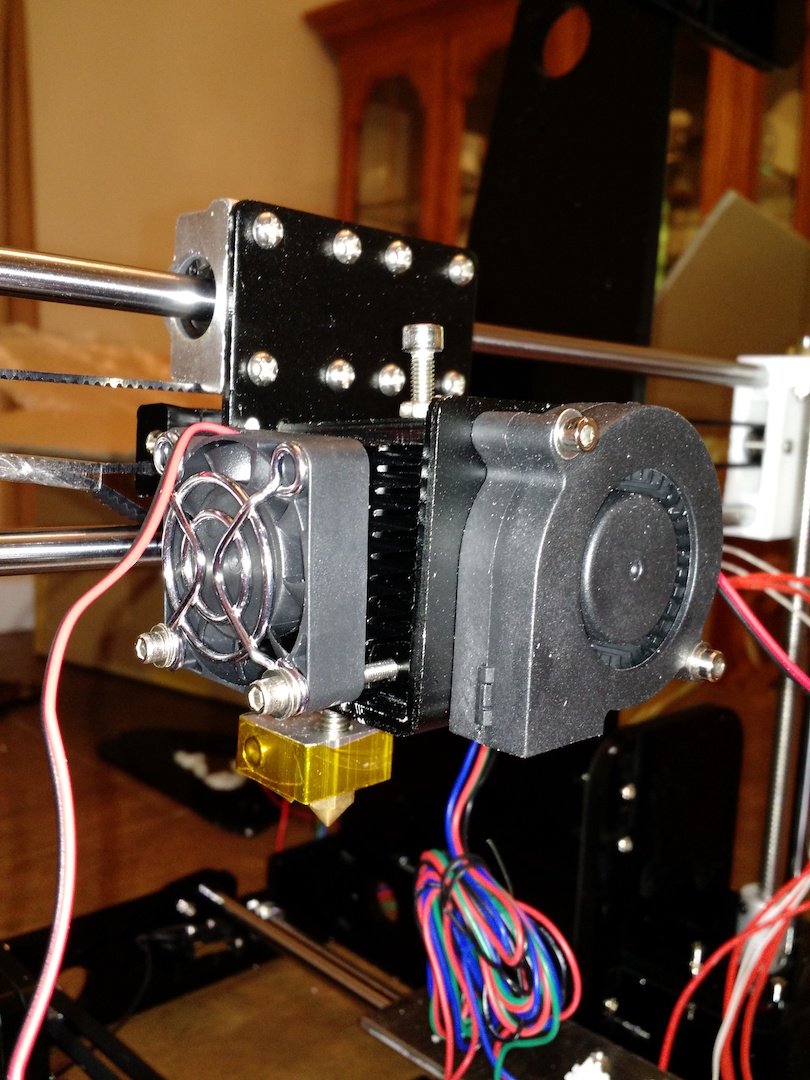

QUESTION: Close up of the filament path in the feed mechanism.

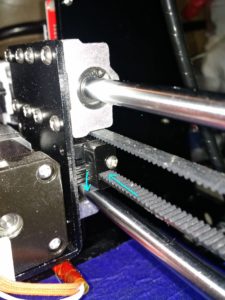

Here is a photo of PLA filament as it enters the extruder nozzle. Yep, it just sits in there and can be difficult to get in the tube at the bottom if the filament is curved (as most are). Make sure you press down on the thumb screw area when installing the filament (while supporting the extruder from the bottom). This compresses the spring and moves the silver wheel away from the motor driven gear to allow the filament to pass to the intake tube. If the nozzle is hot, you should see the plastic squirt out of the nozzle when successful.

Please note: The cooling fan and exchanger has been removed to show the filament path (these need to be reinstalled). Also, the cartridge heater and temperature sensor have been pulled out for this photo… These must be in place before trying to heat anything (else the heater will be damaged).

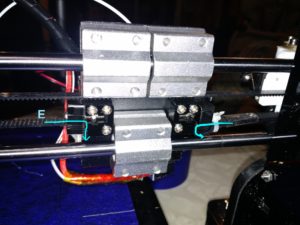

QUESTION: Can you show a photo of the drive belt connections?

The drive belt is held in by these little gripper teeth with two parts. Push the belt through the part with the slot, insert the screw, and tighten into the part that mounts on the extruder assembly (with teeth facing outwards to grip the belt).

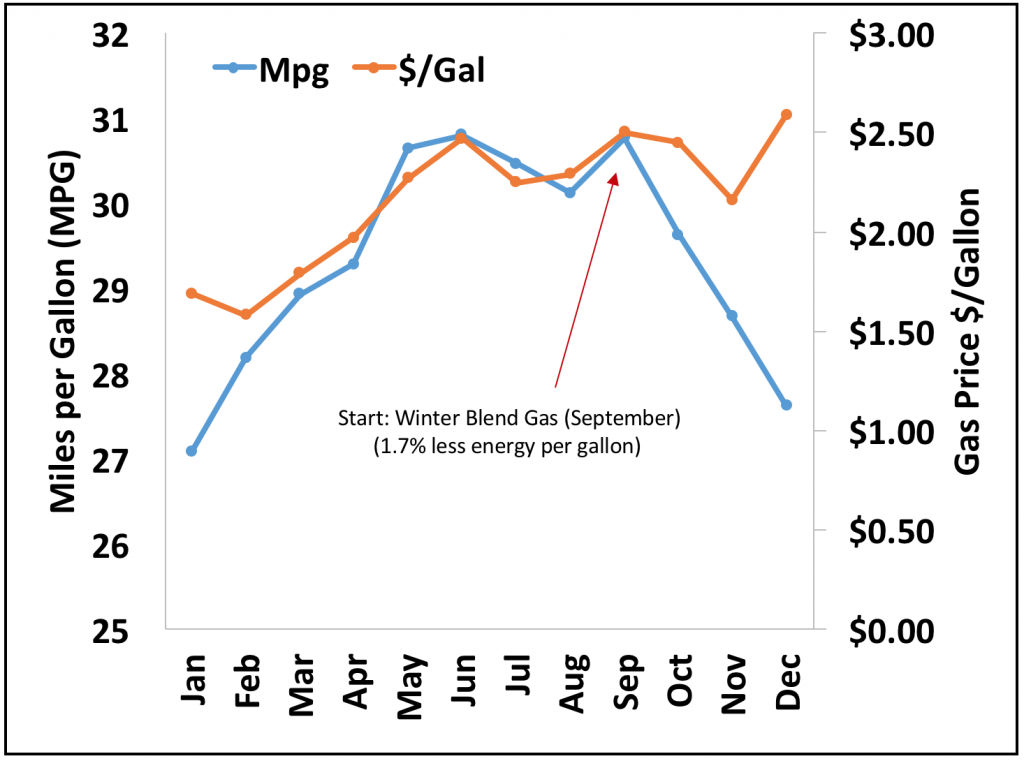

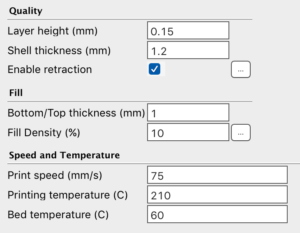

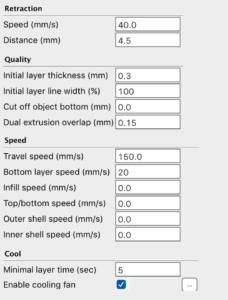

QUESTION: Print not going well. What are your typical print settings?

I have been using PLA and had a few problems. First, make sure your print bed is level and very close to the printer nozzle (0.3 mm is my initial layer thickness). Move the printer nozzle to all corners of the printer bed, make sure the distances are the same at all corners. The build bed cannot touch the nozzle! Yet, if it is too far way the material will not stick. I have tried glue stick, wet glue coating, masking tape, bare metal and now the cheapest painter’s tape possible – it didn’t seem to matter as much as the nozzle position to the print bed. The closeness is important. Almost touching…

For the settings: Too hot, it warps, too cold it doesn’t stick, too much inner fill and the part can curl up into a ball (this happened to me when I tried to print a flat part). Too hot of an extruder and the part comes looking melted. Too fast and the extruder just grinds away and does nothing. Too fine of a build and the layers just melted together loosing all details (I had to lower the temperature to <205 for really fine details to work).

Lately, I have been using Cura with a slightly hotter temperature… It seems to work alright… Here is a screen shot of the settings.

Good Luck!